Pressure Washer Pump Teardown (ProUser PP150 5.5hp 2200psi)

My ‘cross season has gradually gotten more serious, with two bikes and a pressure washer; both vital at last Sunday’s National Trophy. I’ve always wanted a pressure washer anyway (partly for washing bikes but also because I like mechanical things!) and this £100 GumTree special couldn’t be turned down. It’s been good to me so far but it’s clear the previous owner didn’t look after it. I noticed one of the pump mounting bolts had vibrated loose and after some suspicious drips, then loosing a bit of oil, I decided to take the thing apart to learn about it and give it a service.

I’d assumed that I’d find a turbine pump but the design is something I’ve never come across and is really neat. Like a human heart, it works by changing the size of chambers to force the incompressible liquid through one-way valves; using pistons rather than contracting muscle.

Attached to the drive-shaft is a cam in the x-axis, creating an eccentric motion that knocks into, and depresses each piston. Each piston sits above a chamber in the pump casing with one-way valves leading into, and back out.

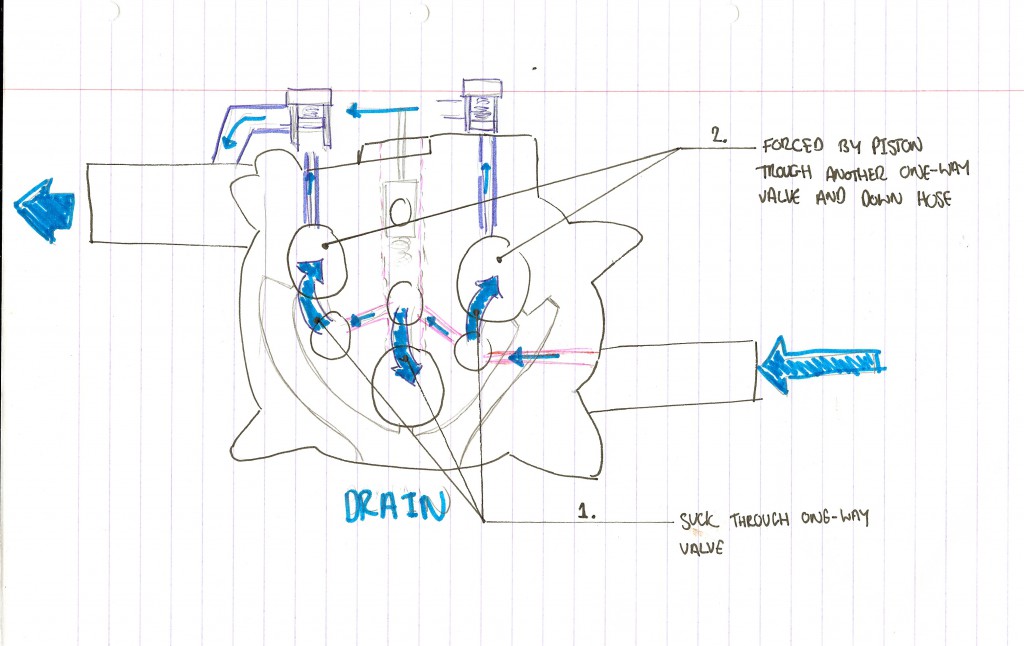

Opening it up, here’s a diagram to figure out how it worked. This is the casting on the right in the video, with the flow other-side overlayed in blue pen. From the inlet, the water is sucked through a one-way valve as the piston pulls back and into the piston chamber. With three pistons pulling at different phases there are three one-way valves to maximise each engine revolution, each chamber filling at a different stroke and creating a more consistent pressure. On the downstroke, the water is forced through another one-way valve positioned vertically at the top here and then along to the outlet. The vertical valves at positioned in series so all the chambers lead to the same final outlet pipe.

Included in the design are various pressure releases to avoid build up, which would damage the valves and maybe even casting. Part of the reason I took it apart in the first place was because it was dripping at the bottom; I assumed the seal had perished. In fact, the chambers all have holes at the top of the stroke which drip down to the base of the pump. The idea being that on the suck stroke, any extra water

will drip away to avoid a water lock. Second to this, the little plastic thing at the top is a sprung pressure valve that releases water from the top manifold if the hose is full; you’re not using the lance. This also leads to the same drip channel. So dripping is normal.

The pump wasn’t too soiled but a blast of carb cleaner and a scrub cleaned up any grime that had built up. The oil certainly needed changing. It was gray with lots of crap in and contaminated with water. It’s meant to be changed after break in and I’ve a feeling the previous owner didn’t bother.

I got some 30wt 4-stroke equipment oil from Halfords and filled to just above the rotating cam (what other pump models seem to suggest). There is a drain hole on the pump but I’m not sure of the exact quantity to put in. Bolted the thing back together with all four bolts so it’s nicely seated now.